Product classification

Aluminum plate fluorocarbon printing

Xintai aluminum plate fluorocarbon coating and printing, with leading equipment and technology, achieving three coatings, three baking, and three-color printing.

hiddenValue

Details Introduction

Aluminum plate fluorocarbon printing is a treatment technology that sprays fluorocarbon coating on the surface of aluminum plates. The following is a detailed introduction to it:

1、 Material and Construction

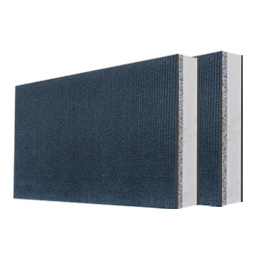

Material: The base material of fluorocarbon coating on aluminum plate is high-quality and high-strength aluminum alloy plate, which has the characteristics of lightweight, high strength, and good plasticity.

Construction: The structure of fluorocarbon sprayed aluminum veneer mainly includes panels, reinforcing ribs, and corner brackets. The common thicknesses are 2.0mm, 2.5mm, and 3.0mm. Corner codes can be formed by panel bending, stamping, or riveting corner codes on small edges. The reinforcing ribs are connected to the surface of the board through welding screws, forming a sturdy whole that enhances the strength and rigidity of the aluminum veneer.

2、 Process principle

Fluorocarbon coating: Fluorocarbon coating is a coating made by baking polyvinylidene fluoride resin as the base material or adding metal aluminum powder as the pigment. Its structure is very stable and can withstand harsh weather and environment for a long time without fading. It has strong corrosion resistance and is also resistant to ultraviolet light.

Electrostatic spraying: Fluorocarbon spraying utilizes the principle of physical electric field force to spray fluorocarbon powder coating onto the surface of aluminum plates through electrostatic spraying equipment. Under the action of static electricity, fluorocarbon powder will uniformly adsorb onto the surface of the aluminum plate, forming a powdery coating. Then, after high-temperature baking and leveling solidification, the powder coating becomes the final coating.

3、 Performance characteristics

Easy to clean: Fluorocarbon coating has self-cleaning properties, and surface dust and stains are easily washed away by rainwater or water, keeping the aluminum plate clean and beautiful.

Strong durability: Fluorocarbon coating can effectively isolate the contact between air and aluminum alloy plates, prevent external pollutants from corroding, and thus extend the service life of aluminum plates.

Good weather resistance: The surface coating has excellent weather resistance and UV resistance, which can resist the erosion of harsh weather, maintain long-lasting color stability, and is not easy to fade.

Rich colors: Fluorocarbon sprayed aluminum veneer has a wide range of colors, bright and beautiful, and good texture, which can meet the needs of different customers to the maximum extent.

4、 Application Fields

Fluorocarbon sprayed aluminum veneer is widely used in fields such as building curtain walls, interior decoration, billboards, etc. due to its excellent performance and diverse color options. It can not only enhance the aesthetics and sense of grade of buildings, but also protect them from the erosion of harsh weather and extend their service life.

In summary, fluorocarbon spraying on aluminum plates is a treatment technology that sprays fluorocarbon coatings on the surface of aluminum plates. It has the characteristics of easy cleaning, strong durability, good weather resistance, and rich colors, and is widely used in fields such as construction and decoration.

Key words:

Product inquiry

Note: Please leave your phone number or E-mail and our professionals will contact you as soon as possible!